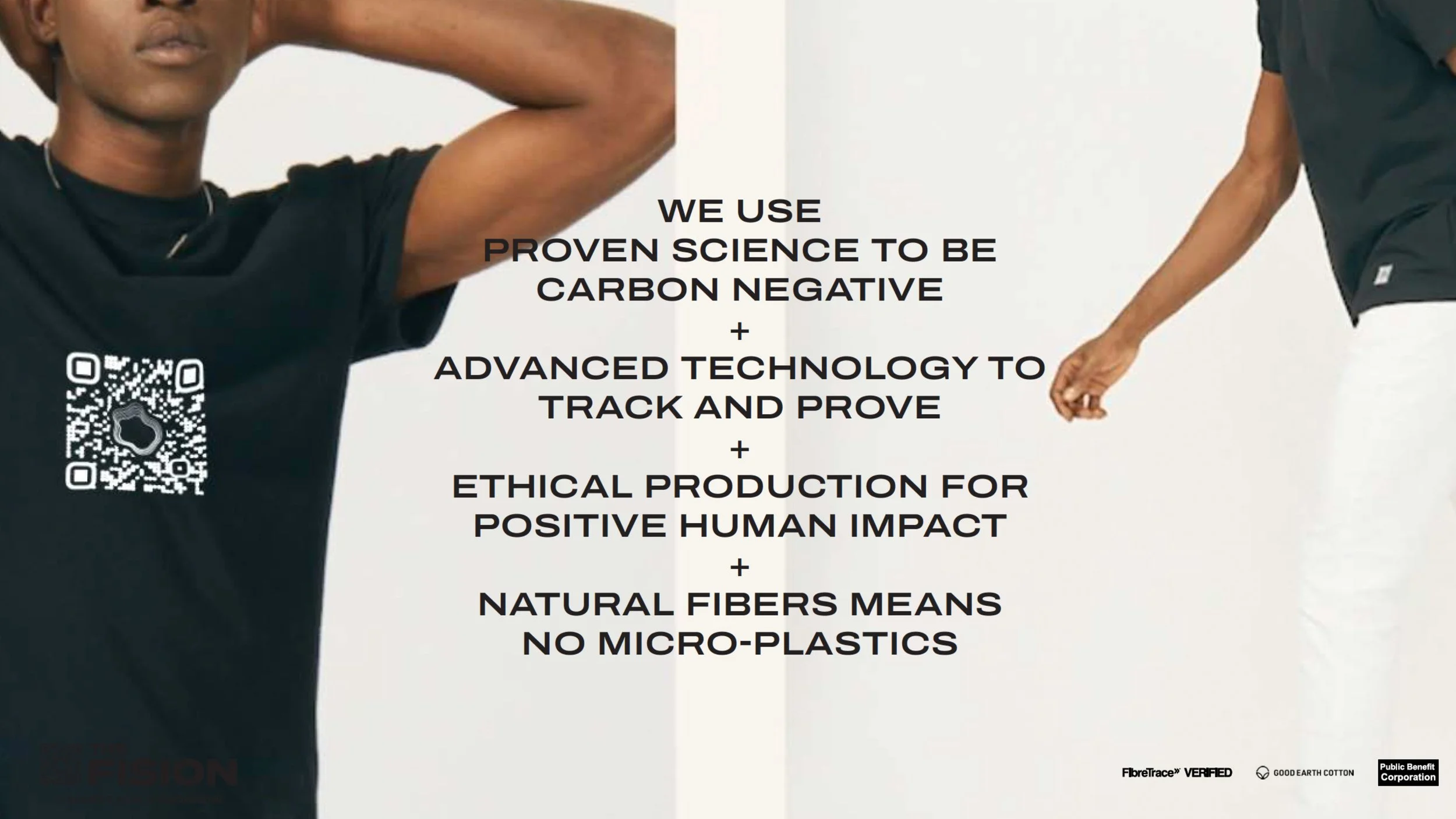

100% regenerative cotton tees with blockchain-enabled supply chain transparency

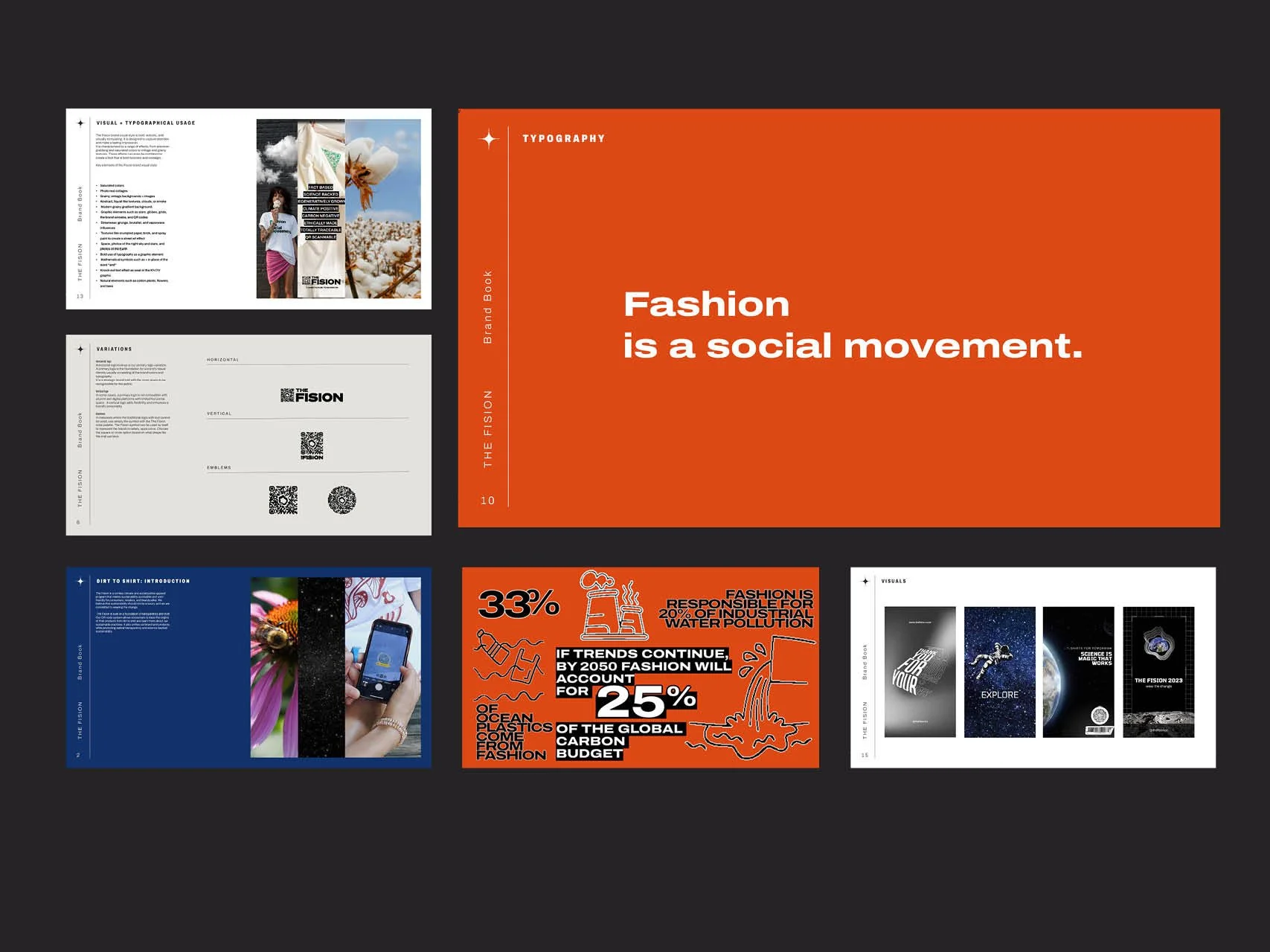

The Fision set out to create tees that told the full story of their journey — from farm to finished garment. I partnered with them to translate that vision into a scalable, fully traceable product line made in Los Angeles.

The Fision – Building a Fully Traceable Tee

When Josh Gelder founded The Fision, his vision was clear: create a brand that put transparency at the heart of fashion. He wanted to launch a line of 100% cotton tees made from regeneratively grown fiber, with every step of the supply chain traceable and accessible to the customer. The idea was bold, but the team lacked the apparel knowledge to make it happen.

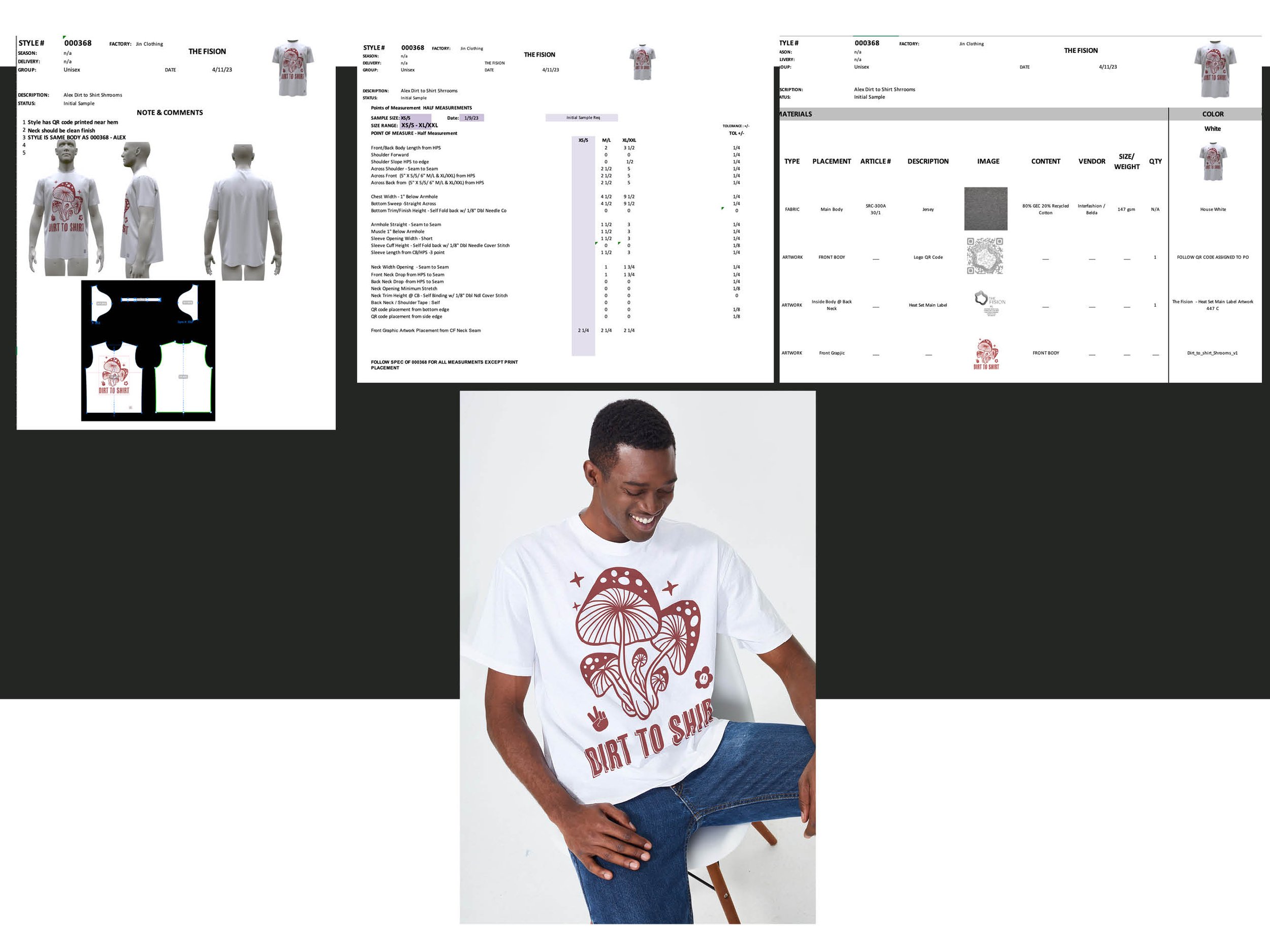

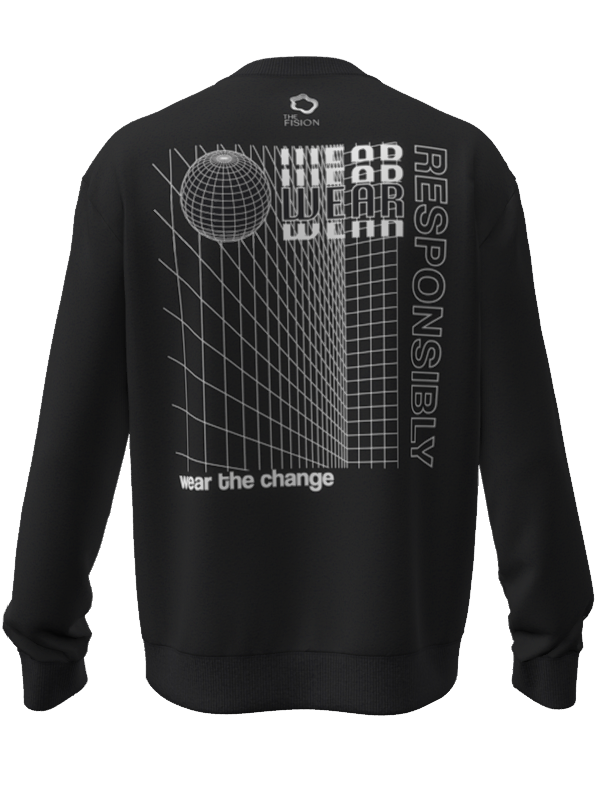

The Fision needed someone who could bridge concept and execution: from fit and technical design to QR code artwork and production. We started by grounding ourselves in the fabric and the mission. Once those anchors were set, I developed silhouettes that would highlight the cotton’s quality and worked with the team to design graphics that reflected the brand’s ethos, including custom QR codes for the traceability story.

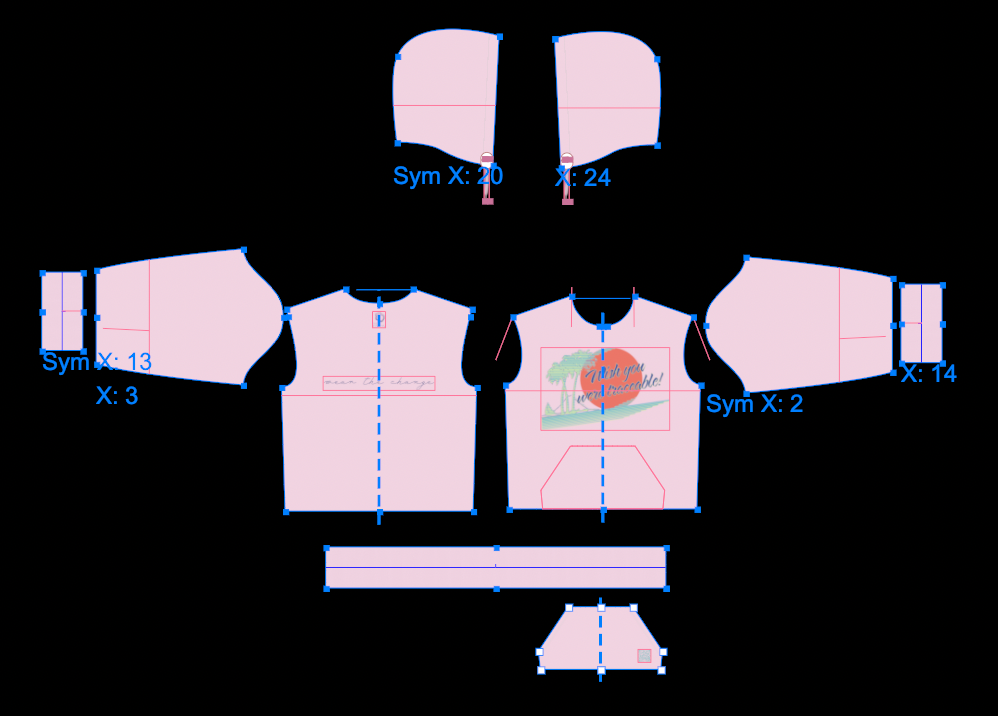

To bring ideas to life, I used Browzwear to build 3D models that served both as design tools and as assets for early marketing. From there, I created tech packs, coordinated prototypes, and guided the fit process. Alongside the development work, I supported photoshoots and marketing prep, ensuring the final product felt cohesive across design, production, and storytelling.

“Cristina is not only incredibly creative but also practical, reliable and extremely efficient. Without question, she’s my go-to designer! Highly recommended.”

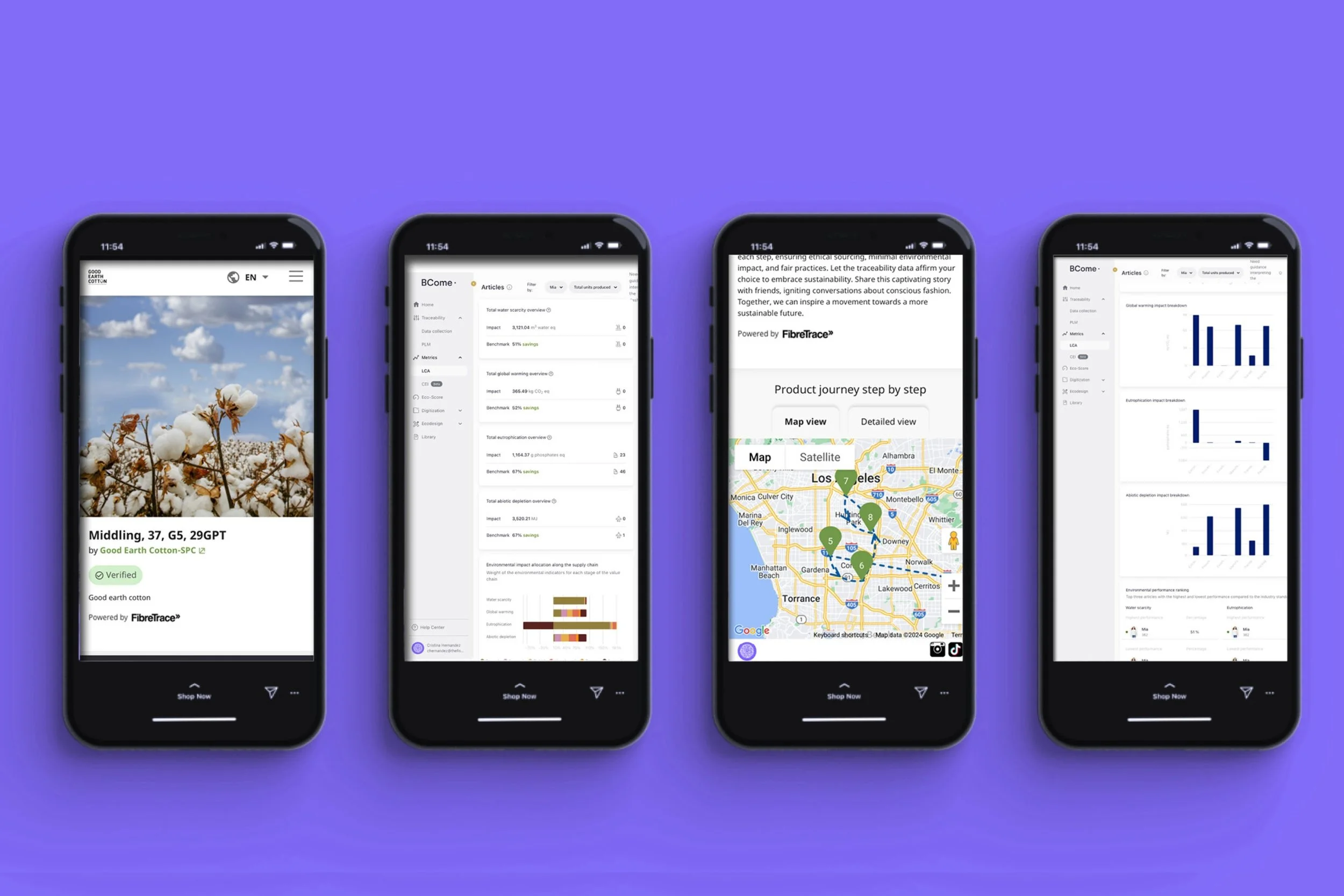

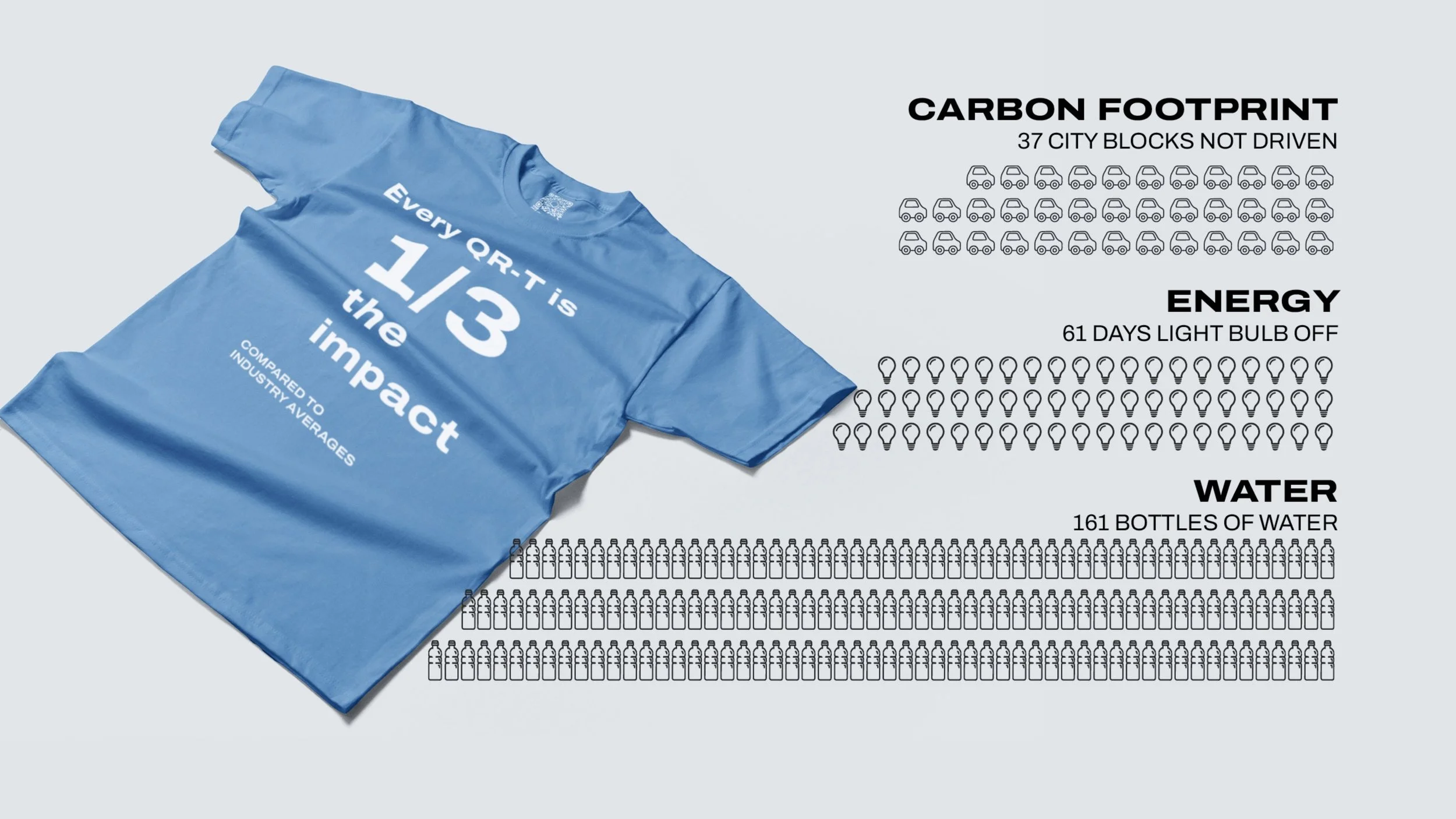

The result was a tee program that did exactly what Josh had envisioned: garments that not only fit well and sold well, but also connected customers directly to their origin. Each tee carried FibreTrace blockchain-enabled tracking, and we were able to support the brand’s commitment to accountability by facilitating a cradle-to-gate LCA with BCome. From yarn grown in Australia to spinning in Spain to knitting, dyeing, and printing in the U.S., the entire journey was documented and verifiable.

For me, this project stood out because it married technical precision with purpose. It was proof that even a startup with limited resources could launch a product that holds its own in terms of design, fit, and market appeal — while pushing boundaries in supply chain transparency. For The Fision, the collaboration gave them not just a product but a replicable process for building garments that matched their vision.

2,000+ Units Produced

Cut, Sewn, and Dyed in Los Angeles

1/3 The Impact

Each tee carried a third of the footprint of a conventional cotton tee

100% Traceable Cotton

Dirt to shirt, verified with FiberTrace

Want these results for your project?

Book a Free Call to Discuss Your Project